Which project

can we help you with?

Blasting, grinding, cutting, infilling – to achieve a perfect result our customers’ applications are as varied as our product range. Whether you are involved with highly technical precision engineering or work as a blasting contractor, we will find solutions to meet your individual requirements. Let us advice you.

Anti-Skid

Fettling

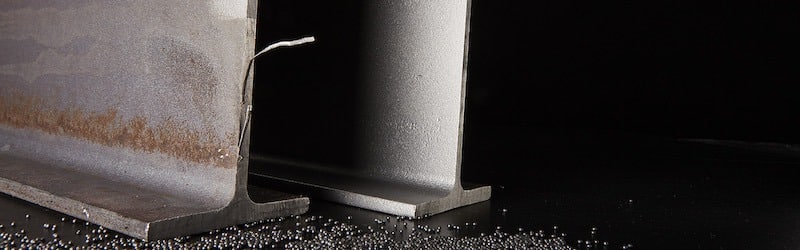

Casting cleaning – The risers (feeder) are removed from the castings by means of cutting grinding or cutting torches. The contour is then smoothed by grinding sharp edges, splinters, burrs and connection points. In order to remove the grinding marks and give the surface a uniform surface appearance, a final jet path takes place.

Depending on the casting material, a ferritic or austenitic round grain is blasted. The particle size is determined by the surface hardness and geometry of the castings as well as the possible system parameters.

Blast Cleaning

With blast cleaning, the aim is to remove any unwanted residue or dirt from components. A slight change in the surface properties of the component may be partially required. A suitable abrasive and a gentle blast process ensure that no abrasion occurs, and that the part is only cleaned when treated.

Coated And Bonded Abrasives

The mineral crystals in an abrasive tool efficiently function as cutting edges to shape a substrate.

Fused aluminas and silicon carbides have proven to be particularly effective, possessing optimum properties for this application due to their hardness and sharp edges.

Deburring

Deburring by blasting is a reliable and economical solution for the removal of these undesirable irregularities.

Rust Removal

<img src=”/wp-content/uploads/entrosten-banner-small.jpg” alt=”Entrosten”>Rust can completely destroy metals, so it is essential to remove it promptly and thoroughly from oxidised areas . There are a variety of solutions to accomplish this, however rust removal by blasting has many advantages over other processes.

In addition to its low impact environmental-friendliness, this application is very precise, and gentle enough to fully preserve component sections.

Jeans Blasting

Masonary Cleaning

A cost-effective, environmentally-friendly, chemical-free solution is to clean buildings with the help of blasting media. This removes all types of contamination whilst keeping substance loss on the substrate itself as low as possible.

Matt / Satin Blasting

Precison Blasting

Paint Stripping

A popular area for this application is the restoration of classic cars, in which enthusiasts attach particular importance to authenticity.

Our high-quality reusable blast media allow effective and thorough paint stripping of various parts.

Polishing

Polishing requires a premium abrasive with a closely controlled grain size. The sizing does not allow for any tolerances, and must correspond exactly to the required specification, otherwise scratches may occur in the polishing process.

When it comes to polishing, Kuhmichel is a renowned supplier throughout Europe.

Our polishing customers rely on our consistently high-quality abrasives, which are supplied with the relevant documentation.

Shape Blasting

Compressive residual stresses are induced in the component by blasting or peening.

With thinly-walled components, this results in forming and simultaneous hardening.

Through this process, highly stressed components can be shaped as desired, and fatigue strength can be improved.

Sand Removal

Parts cast in sand moulds must undergo a post-treatment step to free them from the adhering sand. This is done to a large extent in blast wheel blast cleaning systems in which round metal grit made of cast steel or stainless steel is used. The decisive factor in the choice of abrasive is whether the casting itself consists of ferritic or ferrite-free materials.

The optimum ratio of volume to the surface of the round grain achieves the desired impact force. Since a complete cleaning of the workpieces is just as important as a homogeneous covering of the surface, the choice of grain size plays a major role.

Shot Peening

During shot peening, residual compressive stresses are induced by using round grain (shot).

This causes the first tenth of a millimeter of the component edge layer to solidify.

Dynamically stressed components, e.g. springs, gears, axle parts and turbines, may through this process achieve a significantly longer service life, and also have their dimensions reduced.

Vapour Blasting

The term vapour blasting refers to a gentle blasting application, which removes impurities from a component but does not attack its substance. Many people know this blasting process from the cleaning of buildings or the restoration of vintage cars.

Structural Blasting

Structural blasting creates a homogeneous surface which meets the highest technical and optical requirements, by defining and roughening the component.

With the many possibilities of this application, it is crucial to determine both the right blast media and the right blast process in order to achieve the desired parameters, such as roughness, slip resistance, and degree of gloss and brightness of the surface.

Surface Finishing

Surface Preparation

Surface Preparation

The reason for this is the surface topography created by this process, which enlarges the surface of the workpiece and thus provides the coating with more surface area for adhesion.

Sweep Blasting

The term sweep blasting refers to a special form of blasting in which, for example, galvanized surfaces are carefully roughened in order to improve their adhesive strength for subsequent coatings.

Sweeping differs from surface preparation in that the abrasive hits the surface at a very acute angle.

In addition, reduced pressure is used to carefully roughen the zinc layer without penetrating it.

To ensure the exclusion of corrosion, only mineral and iron-free abrasives, such as fused alumina or garnet sand, are used.

Water Jet Cutting

By adding abrasive material to the water jet cutting process, extremely hard materials can be cut without heat generation. The water/abrasive mixture is accelerated to almost the speed of sound at a pressure of up to 6400 bar. A high degree of precision, high cutting speeds and short set-up times characterise this technology.

Kuhmichel offers suitable abrasives for all systems and applications.

Do you require assistance?

We will be happy to help you!

Contact

Any Questions?

This site is protected by Google reCAPTCHA.We use an extra cookie for its essential functionality.Please click on “Agree” to accept.